Why is the edge of the masking tape curled up?

by:Gangyuan

2022-12-23

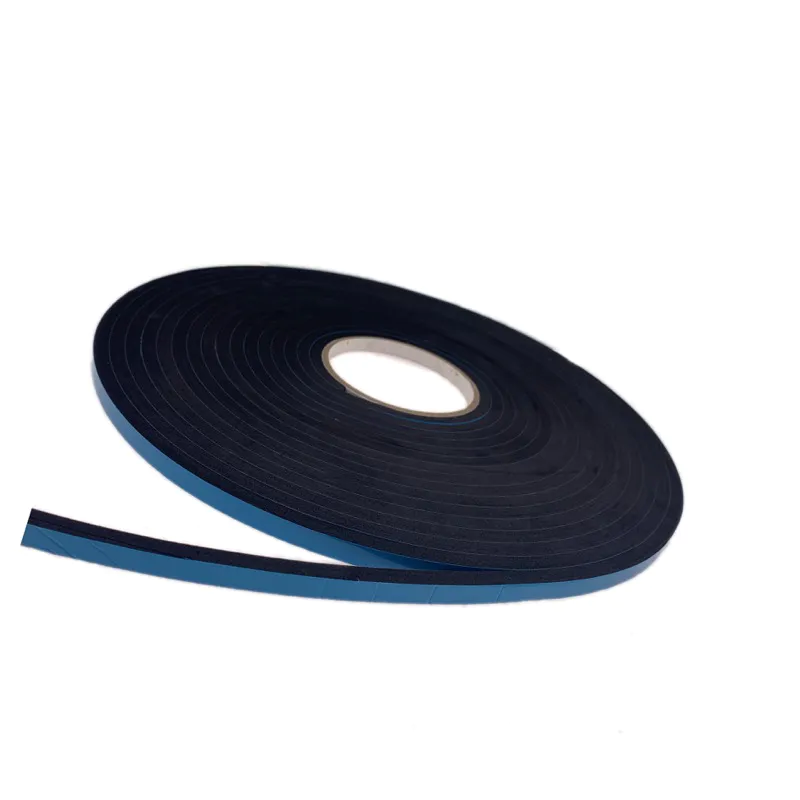

Masking tape is a roll-shaped adhesive tape made of masking paper and pressure-sensitive glue as the main raw materials. The pressure-sensitive adhesive is coated on the masking paper, and the other side is coated with anti-sticking material. It has the characteristics of high temperature resistance, good resistance to chemical solvents, high adhesion, softness and no adhesive residue after tearing.

What are the reasons why the edge of the masking tape is lifted?

1. The viscosity of the glue is too weak: the appropriate glue material should be selected;

2. The pressure of the labeling machine is not enough: the reasons and solutions are as above;

3. Poor film tension control: After removing the label of the correct film from the backing paper, it will be flat and will not bend. After labeling, the label can maintain excellent followability; the label with too tight tension comes from the backing paper. After removal, the label turns back, causing the label edge to debond and warp after application;

4 Improper selection of adhesives: When selecting self-adhesive adhesives, first determine whether the adhesive required for self-adhesive labels is permanent or removable, whether it is pasted or reposted. And whether the product has special requirements on the chemical properties of the dry sticky label adhesive. For example, on large curved surfaces, the surface material should not be selected from thick or hard paper materials (such as mirror coated paper). Film or thin soft paper materials and adhesives with high initial viscosity; for containers that require hot filling, the surface material of the adhesive material should be selected from film materials and good initial viscosity

5. Label surface material: When selecting the label surface material, you should consider whether the label object is a plane or a curved surface, whether it is a large diameter or a small diameter, whether it is a single curved surface or a spherical surface, whether it is a rigid body or compressible deformation, these indicators They are the same as surface material selection. There is a direct relationship. Soft bottles should be made of soft materials, such as PE, PVC, unstretched PP and PE and PP composite materials. Hard bottles can consider PET, BOPP, PS materials;

6. The shape design of the bottle is unreasonable: the reasonable design should be that the surface of the bottle is flat (mainly the design of flat bottles and round bottles), but if the surface is partly spherical within the label range, use paper labels. When labeling, the label area is large, and the two sides of the lower end of the label are easy to wrinkle.

The above six reasons are increasing. For masking tape to work best, we must avoid the six appearances above. The most important thing is the first one. We have to choose at the time of purchase. Good quality, so long service life

Custom message