Is vinyl electrical tape waterproof?

Is Vinyl Electrical Tape Waterproof?

Introduction

Vinyl electrical tape is a commonly used tool for insulating electrical wires and providing protection against moisture and other elements. However, it is crucial to understand whether vinyl electrical tape is truly waterproof before relying on it in wet or damp environments. In this article, we will explore the waterproof properties of vinyl electrical tape and discuss its effectiveness in various scenarios. So let's dive in!

Understanding Vinyl Electrical Tape

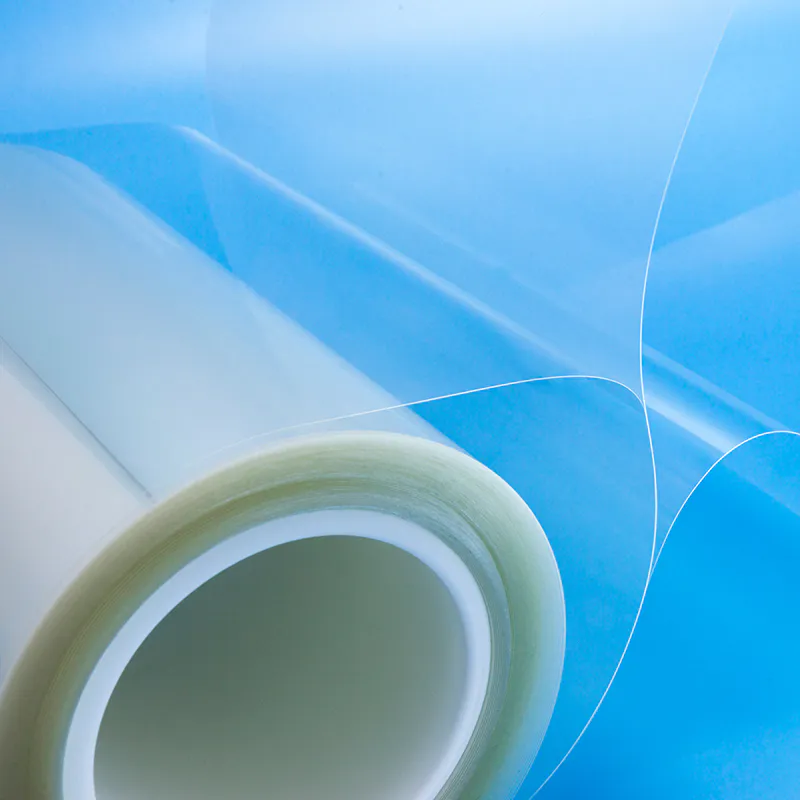

Vinyl electrical tape is a type of pressure-sensitive adhesive tape primarily used for insulating electrical wires. It is made from a combination of polyvinyl chloride (PVC) and a rubber-based adhesive. The tape is known for its excellent electrical insulation properties, effectively preventing electrical hazards and ensuring safety in electrical installations.

Waterproof Properties of Vinyl Electrical Tape

Many people assume that vinyl electrical tape is waterproof due to its highly adhesive properties. However, it is important to note that while vinyl electrical tape provides a degree of protection against moisture and humidity, it is not entirely waterproof.

Vinyl electrical tape can resist mild exposure to moisture and humidity found in everyday environments. Its adhesive is specially designed to protect electrical connections from light splashes, condensation, and normal humidity levels. When properly applied, the tape can maintain its insulation properties even in mildly damp conditions.

Waterproof vs. Water-Resistant

To better understand the limitations of vinyl electrical tape, it is essential to differentiate between waterproof and water-resistant properties. Waterproof materials are completely impervious to water, preventing any penetration or damage. On the other hand, water-resistant materials can withstand limited exposure to water but are not entirely impervious.

Vinyl electrical tape falls into the water-resistant category. While it can repel light moisture under normal circumstances, prolonged exposure or immersion in water can lead to compromised insulation. Therefore, caution should be exercised when using vinyl electrical tape in areas with a higher risk of water exposure.

Limitations in Extreme Environments

Vinyl electrical tape's water resistance diminishes significantly in extreme environments such as heavy rainfall, submersion, or areas prone to frequent water contact. In these cases, the tape may begin to lose its adhesive properties and allow moisture to seep through, potentially compromising electrical connections.

For areas that are consistently exposed to water or the outdoors, alternative solutions should be considered to ensure long-term protection against moisture. These may include heat shrink tubing, silicone-based tapes, or liquid electrical tapes, which are more suitable for waterproofing applications.

Alternative Solutions for Waterproofing

When working in areas where waterproofing is crucial, it is recommended to explore alternative options that offer greater resistance to water. Heat shrink tubing, for example, is a popular choice for providing a watertight seal around electrical connections. It shrinks when heat is applied, providing a tight, protective covering.

Silicone-based tapes are another viable alternative. These tapes are specifically designed to be waterproof and are highly resistant to moisture, chemicals, and extreme temperatures. Liquid electrical tapes, available in brushable or spray-on forms, create a protective barrier that effectively seals and insulates electrical connections.

Tips for Using Vinyl Electrical Tape Effectively

Although vinyl electrical tape is not entirely waterproof, it can still be used effectively in various applications with careful consideration. Here are some tips to maximize its performance:

1. Ensure a clean and dry surface before applying the tape.

2. Use multiple layers of tape to enhance its water resistance.

3. Overlap the tape wraps to create a more secure seal.

4. Inspect the tape regularly for signs of wear or degradation.

5. In high-water-risk areas, consider alternative waterproofing methods.

Conclusion

In summary, while vinyl electrical tape provides some resistance to moisture and humidity, it is not entirely waterproof. Understanding its limitations is crucial to prevent any potential electrical hazards or failures. By considering alternative solutions and following proper application techniques, you can effectively use vinyl electrical tape for insulation and protection in most electrical installations.