What are the two types of double-sided tape?

Double-sided tape is a versatile adhesive that is widely used for both industrial and household purposes. It is a type of tape that is coated with adhesive on both sides, allowing it to stick to two surfaces simultaneously. This flexible adhesive solution offers numerous advantages, such as providing a clean and permanent bond, being easy to use, and allowing for a variety of applications.

There are two main types of double-sided tape that are commonly used: foam-based and film-based. Each type offers distinct properties and characteristics. Let's dive into each type to understand their features, applications, and benefits in more detail.

1. Foam-Based Double-Sided Tape:

Foam-based double-sided tape is composed of a layer of adhesive coated on both sides of a foam carrier. The foam carrier can be made from various materials, such as acrylic, polyethylene, or polyurethane. This type of tape often comes with a protective liner that needs to be removed before application.

Foam-based double-sided tape offers several advantages. First, it provides excellent bonding strength and conformability, allowing it to adhere to irregular and textured surfaces. The foam carrier also acts as a shock absorber, making it suitable for applications that require vibration or impact resistance. Moreover, foam tapes offer good sealing and cushioning properties, making them ideal for applications in gasketing, sound dampening, and weather stripping.

Common applications of foam-based double-sided tape include mounting of signs, emblems, and trim in the automotive industry. It is also widely used in the construction sector for bonding interior and exterior panels, mirrors, and glass. Foam-based tapes are favored in the electronics industry as well, where they secure components and PCBs (Printed Circuit Boards) while providing electrical insulation.

2. Film-Based Double-Sided Tape:

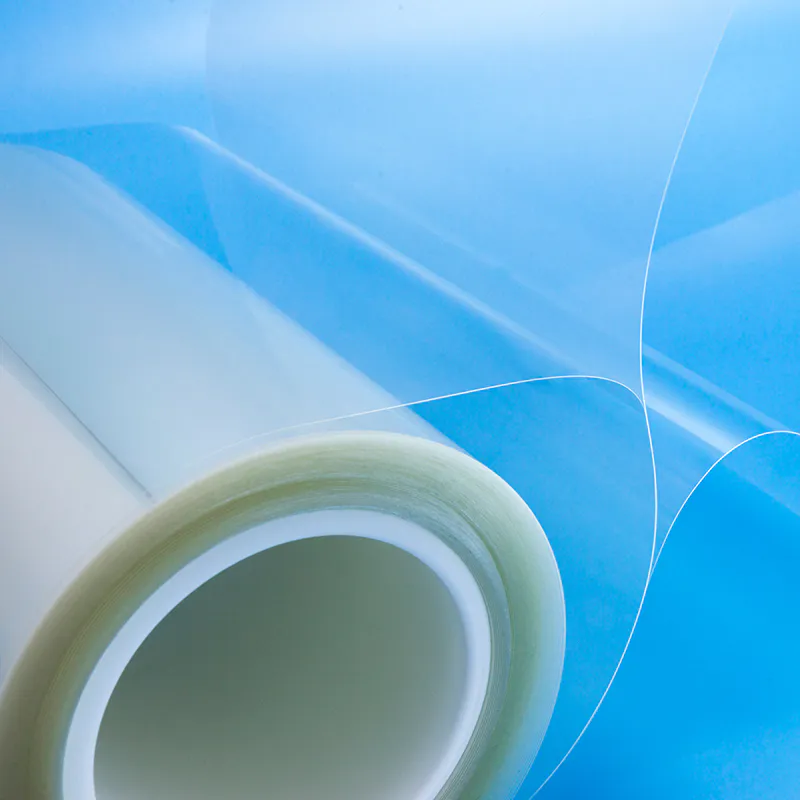

Film-based double-sided tape consists of a layer of adhesive coated on both sides of a thin film carrier. The film carrier is commonly made of materials like polyester, polypropylene, or PVC. Similar to foam-based tape, film-based tape also has a protective liner that needs to be peeled off during application.

Film-based double-sided tape offers several advantages. Its thin and flexible nature makes it ideal for applications where a low-profile bond is required, or where the presence of the tape needs to be inconspicuous. Moreover, film-based tapes often provide high transparency, enabling them to be used in applications where aesthetics are crucial.

Applications of film-based double-sided tape include bonding of transparent materials, such as glass, acrylic, or polycarbonate. It is commonly used in the manufacturing of electronic devices, where it securely attaches LCD screens, touch panels, or touchscreen displays. Film-based tapes are also extensively employed in the packaging industry and for general mounting purposes.

In conclusion, double-sided tape is an invaluable adhesive solution that comes in two main types: foam-based and film-based. Foam-based tape excels in offering bonding strength, conformability, and cushioning properties, making it suitable for various industrial applications. On the other hand, film-based tape provides a thin and inconspicuous bond, making it suitable for applications where aesthetics and transparency are vital.

Whether you need to mount an object, bond different materials, or secure an item while maintaining its appearance, double-sided tape provides a reliable and convenient solution. Choose the type of double-sided tape that best suits your specific requirements and enjoy its ease of use and versatility in countless applications.