Is Bopp the same as polypropylene?

An Introduction to Bopp and Polypropylene

Bopp (Biaxially Oriented Polypropylene) and polypropylene are terms that are often used interchangeably, leading to confusion regarding their actual relationship. However, it is important to understand that Bopp is not the same as polypropylene, but rather a type of film produced from the polypropylene polymer.

Manufacturing Process: How are Bopp and Polypropylene Produced?

The production process of Bopp and polypropylene follows a similar path up until a certain point. Both Bopp and polypropylene start with the extraction of propylene, a thermoplastic polymer, derived from crude oil or natural gas.

Once propylene is obtained, the manufacturing journey diverges. For the polypropylene production, the propylene is polymerized using catalysts and additives, resulting in a solid resin. This resin is then melted and shaped into various forms like sheets, fibers, or pellets which can be further processed into a wide range of consumer and industrial products.

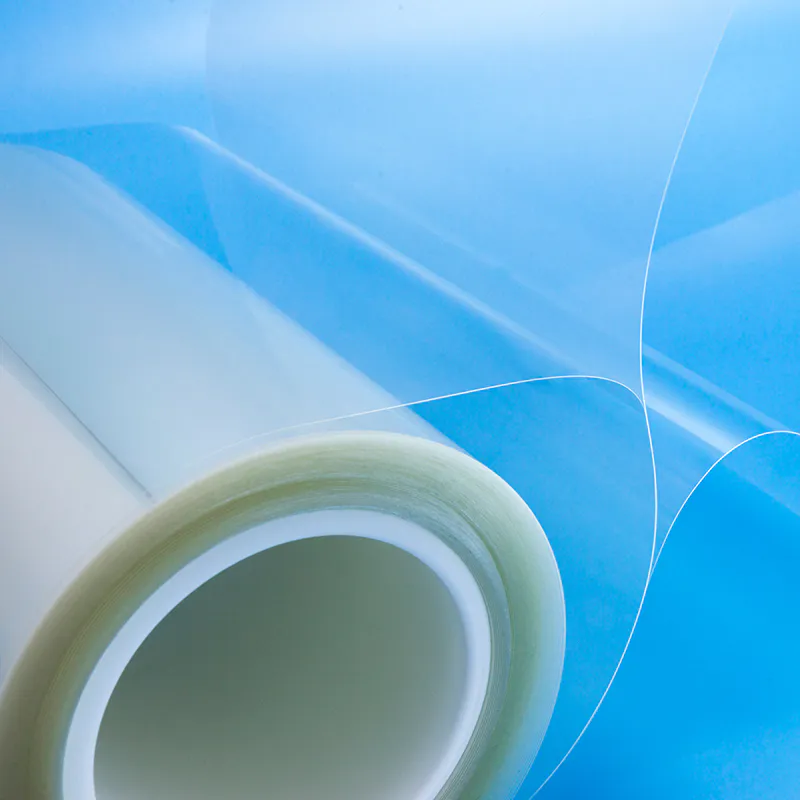

To produce Bopp, the polypropylene resin undergoes a stretching process called biaxial orientation. This involves stretching the material both mechanically and thermally, allowing it to develop specific properties and a distinct molecular orientation. The biaxially oriented polypropylene film obtained in this process becomes Bopp.

Properties and Characteristics: A Comparative Analysis

Bopp and polypropylene share some common characteristics as they originate from the same raw material, but their properties differ to a considerable extent due to the variation in manufacturing processes.

Polypropylene offers excellent stiffness, chemical resistance, and high melting point. It is durable, lightweight, and has a relatively low cost, making it highly suitable for a broad range of applications. On the other hand, Bopp inherits some properties from polypropylene, such as its high tensile strength and excellent moisture barrier. However, Bopp is also known for its transparency, gloss, and ability to accept printing, making it an ideal choice for packaging materials.

Applications and Uses of Bopp and Polypropylene

Both Bopp and polypropylene find extensive applications in various industries due to their unique properties.

Polypropylene is widely used in automotive parts, medical devices, food packaging, textiles, and household products. Its versatility allows it to be molded into different forms, enabling manufacturers to create a diverse range of products.

Bopp, being a film with remarkable transparency, is often used for flexible packaging, such as food packaging, confectionery wrappers, labels, and adhesive tapes. The glossy appearance of Bopp enhances the visual appeal of products while providing protection against moisture and external contaminants.

Sustainability: Are Bopp and Polypropylene Environmentally Friendly?

Sustainability has become a crucial factor in the modern industrial landscape. When it comes to Bopp and polypropylene, their levels of environmental friendliness are contingent on various factors, including recycling capabilities, energy consumption during manufacturing, and end-of-life disposal options.

Polypropylene has a relatively low environmental impact, as it can be recycled into secondary products such as bins, battery cases, and automotive parts. However, recycling systems for polypropylene are still developing in many regions, leading to a significant amount of this material ending up in landfills.

Bopp, similar to polypropylene, can be recycled, but due to the challenges associated with separating it from other materials, the recycling rate for Bopp is lower. However, advancements in recycling technology and increased awareness of sustainable practices are gradually improving the recycling prospects for both Bopp and polypropylene.

In conclusion, while Bopp is derived from polypropylene, it is not the same material. Both Bopp and polypropylene offer unique properties and find extensive applications in various industries. Understanding the differences and similarities between the two materials is essential for manufacturers and consumers to make informed decisions regarding their suitability for specific uses. Moreover, investing in recycling infrastructure and sustainable practices can further enhance the environmental profile of Bopp and polypropylene, contributing to a more eco-friendly future.